Not known Factual Statements About Premier Aluminum Llc

Table of ContentsSome Known Details About Premier Aluminum Llc Premier Aluminum Llc for BeginnersThe Premier Aluminum Llc IdeasSome Known Details About Premier Aluminum Llc

(https://premieraluminum.edublogs.org/2024/12/12/top-rated-aluminum-casting-company-why-premier-aluminum-llc-stands-out/)Traditionally, a purchaser's key obligation was to discover professional and responsive distributors. Sometimes, buyers presumed that any vendor going to contractually meet the acquisition need was qualified. Making use of low cost and unqualified vendors can cause high quality issues, and lost time and cash in the lengthy run. To help you via the process, below are some things to think about when choosing the appropriate steel casting vendor.

For instance, a company that just makes use of the investment casting process will try to sell you on why that process is best for your application. What if using the sand spreading procedure is best for you and your needs? Instead, look for a provider that supplies a variety of casting procedures so the most effective alternative for YOU is chosen

If dealing with a solitary source for every one of your casting needs is necessary to you, the vendor needs to be varied in its abilities. When incorporated with various other incorporated abilities, this can help simplify and compress the supply base. When picking the appropriate spreading provider, cautious factor to consider should be given to top quality, solution, and cost.

The Ultimate Guide To Premier Aluminum Llc

Purchasers significantly pick spreading distributors who have machining abilities. If the casting provider uncovers a concern during machining, the trouble is solved much faster with no disagreement over whose mistake it is.

What do you require from your spreading vendor? Are you looking for a person to just provide a metal element to your front door or do you require a lot more?

Others will certainly surpass the letter of the PO to aid you conserve money and time. Do you have needs for both ferrous and non-ferrous alloys? Some foundries are limited or specialized. Make certain the distributor can satisfy all your material or alloy demands to remove the demand for multiple distributors.

The 6-Second Trick For Premier Aluminum Llc

Research study the distributor's website. Talk to a sales representative or company associate. Ask a great deal of questions. Visit their facility. Obtain an understanding of what they can do for you and if you can see yourself constructing a solid, mutual partnership with them.

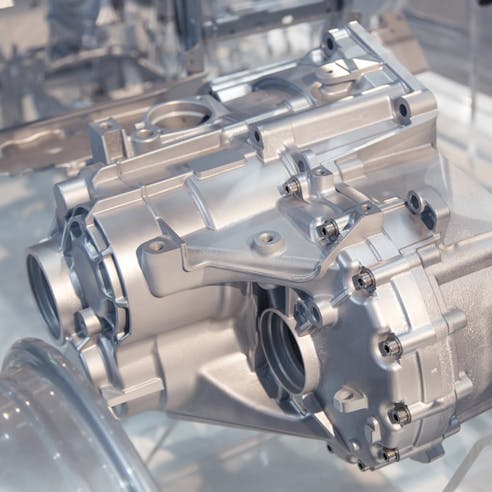

Aluminum is additionally lightweight and has great corrosion resistance, making it suitable for applications where weight and longevity are essential variables. In addition, aluminum spreading is a cost-effective approach of production, as it needs much less energy and resources than various other methods. Iron spreading, on the other hand, involves putting liquified iron into a mold to create a preferred shape.

Little Known Facts About Premier Aluminum Llc.

Iron casting is also able to hold up against high temperature levels, making it appropriate for usage in applications such as engine parts and industrial equipment. Nonetheless, iron spreading can be more expensive than light weight aluminum spreading as a result of the greater cost of basic materials and the energy called for to thaw the iron. When choosing in between aluminum spreading and iron spreading, it is necessary to take into consideration the particular needs of the application.

In conclusion, both aluminum casting and iron spreading have their own special advantages and disadvantages. There are 3 sub-processes that drop under the category of die casting: gravity die casting (or irreversible mold casting), low-pressure die casting and high-pressure die spreading. To obtain to the ended up product, there are 3 primary alloys utilized as die spreading material to select from: zinc, aluminum and magnesium.